Assembly for Disassembly

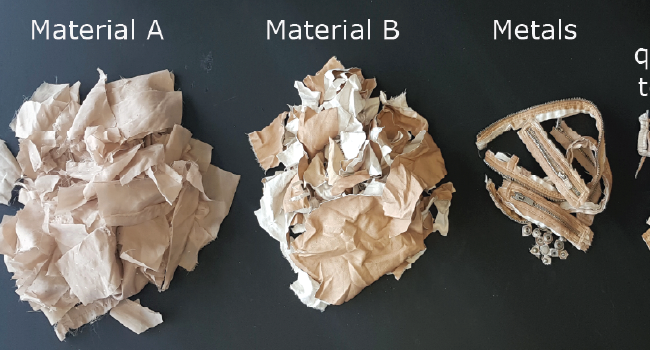

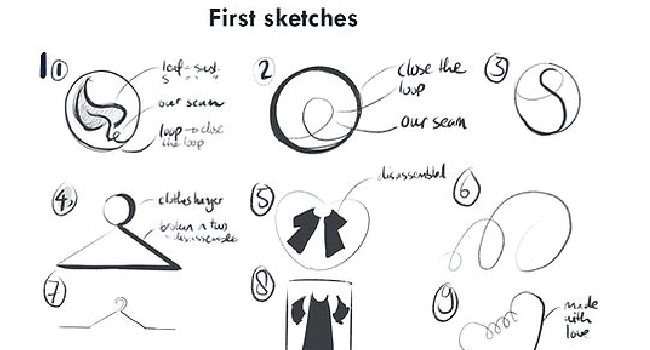

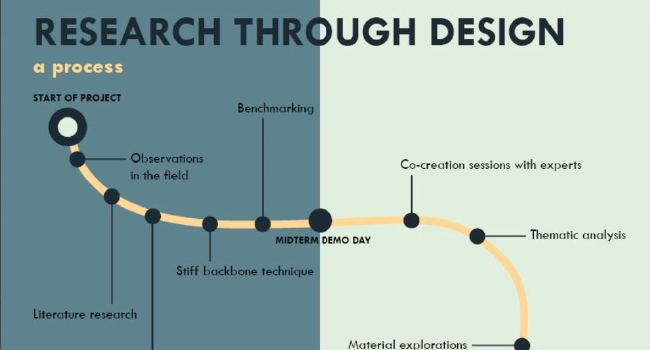

Transitioning to a circular economy (CE) is a widely recognized solution to sustain economic, social and environmental well-being. Resource efficiency should be improved in order to retain the value of materials better. However, to go from a linear to a circular production cycle, garments have to be recovered and further processed. The disassembly of garments is part of this process, which is currently not time-efficient and requires a lot of transportation. A plastic assembly for disassembly technique, which is designed with circularity and localisation in mind, was examined. To research this, co-constructing stories were held with fashion industry experts. As a result, it was found that a localized center and the plastic seam technique are only a small part in the bigger picture of the fashion industry. We can better understand now how to transition into a more sustainable fashion industry by using the plastic seam technique.